Success Story » Design and Manufacturing

How Deshler collaborates to develop award-winning prototypes.

After extensive field research, Amanda Manufacturing created innovative products for the off-road community and launched a new company.

The Challenge

After getting a taste of our partners’ clever tow hook design, new customers from all over the country were eager to see what innovative aftermarket parts they’d come up with next. Answering this call meant extensive research, prototype development and planning for production. The demand was clear and exceptional agility was required.

Deshler leaders assembled a team to deeply engage with the off-road community. They sponsored an Ultra4 race driver, brought prototypes to King of the Hammers and Jeep Beach, and grew close to buggy-building, rock-crawlers and recreational off-roaders. They also learned the community’s clear preferences: superior function is essential, easy integration is preferred, and appearance is also important.

The Prototype Shop

After listening to people at events around the country, Deshler expanded its focus from recovery hooks to include aftermarket parts. The team had heard enthusiasts repeatedly mentioning that bumpers and doors were their priorities for replacement or customization. The Deshler team, including both Amanda Products and Amanda Manufacturing, assembled to review results, thrilled at the opportunity to simultaneously advance engineering innovation and develop a new design aesthetic for the off-road space.

At Deshler, idea-sharing – from anyone on staff – is always encouraged. It should be, considering Deshler’s ongoing growth comes directly from its unique ability to integrate ingenuity with craftsmanship across its companies. This emphasis on risk-taking and equal collaboration has built Deshler’s reputation as a skilled prototyping partnership.

When a staff member or small team has a creative solution to a manufacturing problem, the need to respond to an unusual customer request or issue, or a progressive idea to expand upon a Deshler capacity or product, people listen. Leaders are open and willing to try new ideas, from anyone on the team. Even when workable solutions aren’t developed, they ask what was learned and what pieces of these ideas could be used in a different way, even by a different Deshler company. It’s a collaboration of equals.

Case in point: Amanda Products, Deshler’s customer-facing brand, started with a single idea from an off-road enthusiast on Amanda Manufacturing’s staff. After presenting his proposal to improve the utility and safety of an off-road essential, he worked with fellow fabricators to craft a prototype of the Amanda Products SpeedHook™, with full support of the executive team.

Ideation

In June Deshler gathered its team in a Detroit-area conference room for two full days of brainstorming. Engineers, designers and the Deshler team partnered with Memora, a bi-coastal experience design firm, to lead the ideation process.

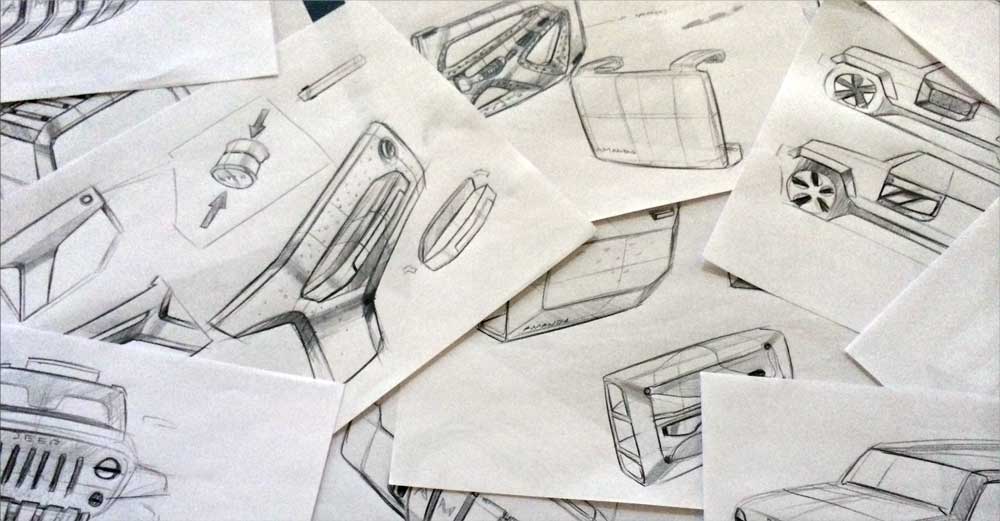

Collaboration was the guiding word. Engineers and designers would work together. Executives would listen and offer perspectives, not directives. Anything would be considered possible. Together they sifted through research on competitive products, photos of extreme and modified vehicles, and feedback Deshler/Amanda Products had collected from the off-roading community. Everyone was told to proceed without limitations, to be creative, even crazy, to consider every angle of a vehicle and imagine what could be done with it. The goal was innovative concepts, period.

Teams broke off for product ideation sessions and were asked to generate as many ideas as possible. None of their results were discarded or judged unworkable before discussion. The freedom to present or say anything was essential to the process. Teams also presented their ideas to each other, generating surprising results, spirited discussion and sticky notes everywhere they looked.

Results

Deshler’s borderless ideation approach led to product prototypes that offered solutions to consumer challenges, were designed for durability and at OE quality, and demanded attention with unusual and bold style choices. Among these were:

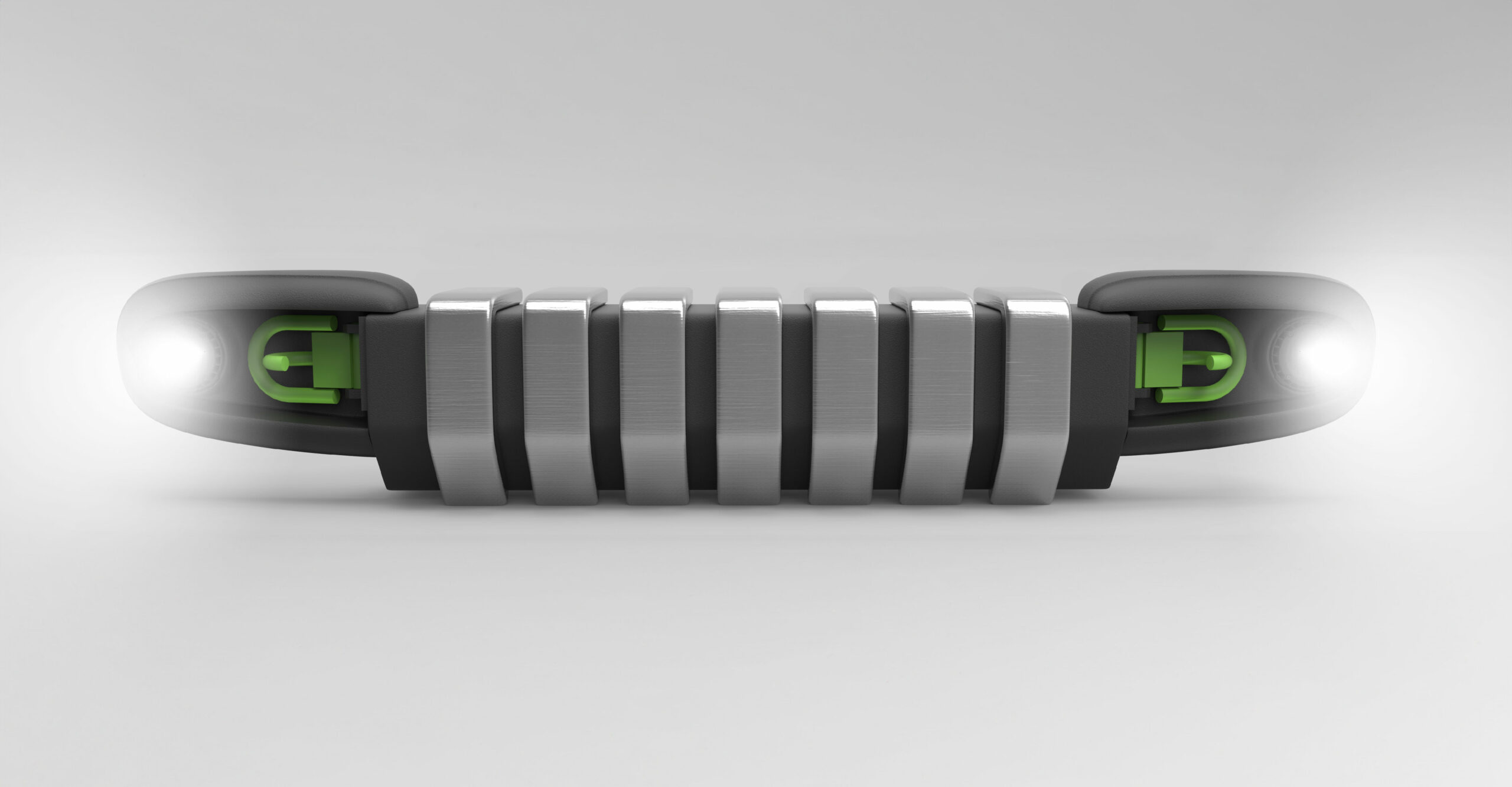

Bumpers aren’t often memorable or easily distinguishable across brands. The team wanted to change this, making them useful, durable, and impossibly cool, while also remaining functional and modifiable.

Doors need to be tough, but also usable. The team produced substantial doors offering roominess, a sense of security, and that opened out of the plane of the body side to allow for additional enhancements.

Transformation

The teams moved forward with a “looks like” (rather than “works like”) prototype. To transform pictures to parts, they needed artisans and fabricators.

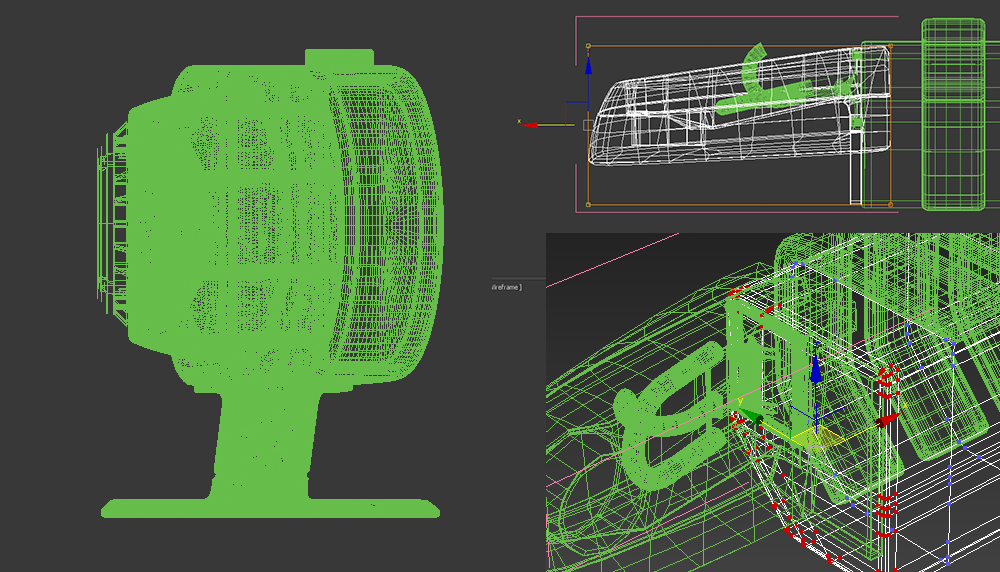

Memora brought in Tom Nemeth, Digital Artist and 3D Modeler – one of seven CG artists to receive an Emmy for “Outstanding Main Title Design” for Game of Thrones. Nemeth was positioned solidly between the approved concept drawings and the hard reality of the team that was working on the vehicle.

Amanda Products required that the bumper be a producible, bolt-on kit for the average Jeep user. To give Nemeth information on fit and available space, the Amanda Manufacturing team physically disassembled the vehicle, painstakingly measuring each part by hand.

Nemeth translated the concept sketches into 3D models while the Amanda Manufacturing team built the main structures of the doors and bumpers. As they fabricated, they sent Nemeth the measurements he needed to modify the models. Once modifications were complete, they were submitted for live reviews.

Deshler executives in the Detroit area, the Amanda Manufacturing team in Ohio, Memora in San Francisco, and Nemeth from his 3D modeling studio in Los Angeles, worked together through mornings, afternoons, evenings and weekends. Modification discussions were continuous, as each tiny adjustment could affect other elements of the 3D model build.

“Staying open to innovative ways of thinking, inviting new ideas from everyone on the team, and then stretching those ideas to their limits…that’s what makes Deshler an excellent place to build strong customer relationships and exciting careers.”

Robert Gruschow

President, Deshler Group

Production

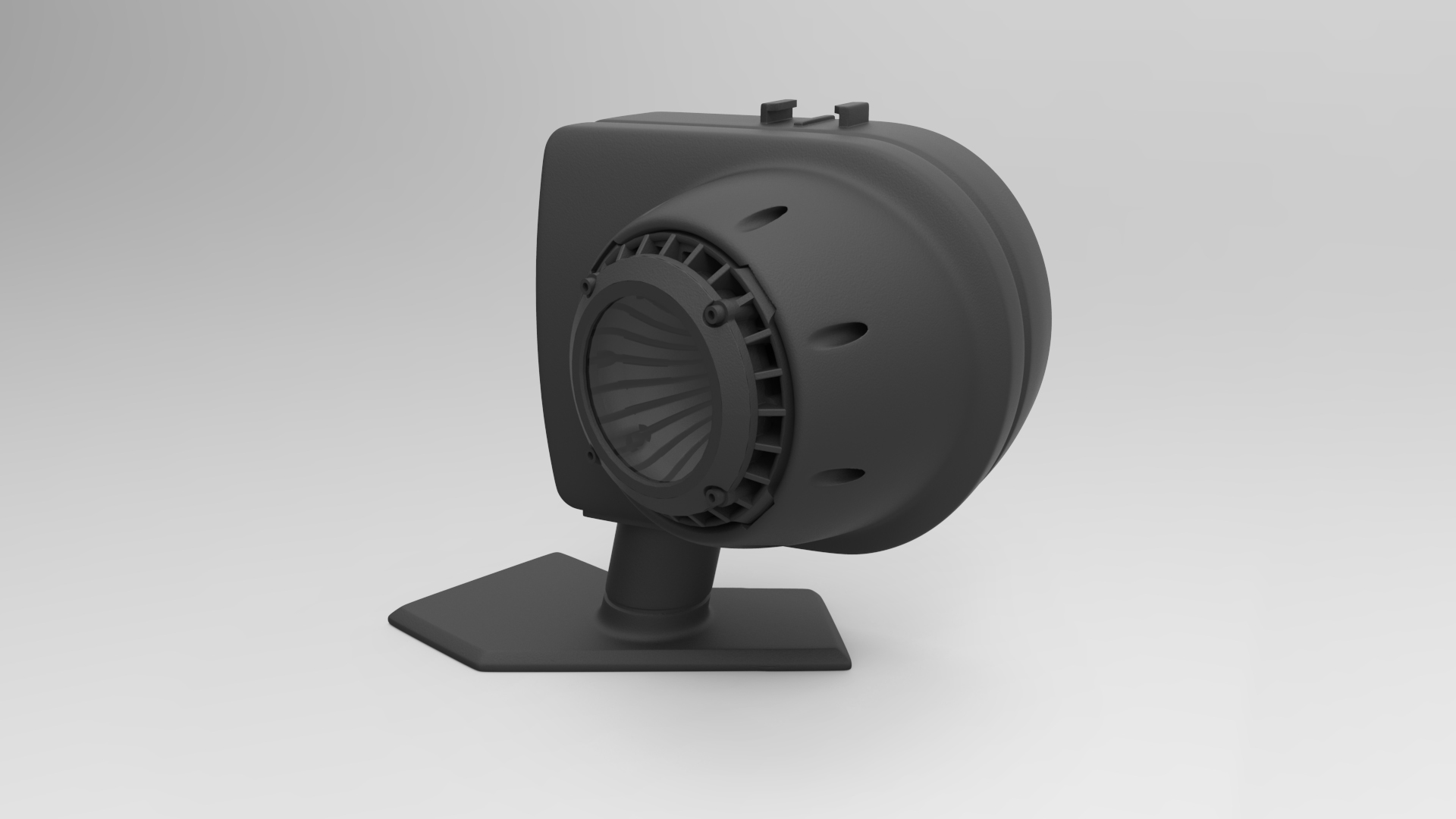

Once complete, Amanda Products took the models to a 3D printing shop which built mock-ups from RapidNylon® – a high end blend of glass filled nylon powder that creates parts with a satin-like finish comparable to production thermoplastics.

Parts were produced from CAD models using laser sintering, a modified additive manufacturing process. A pair of CO2 lasers sintered cross sections of parts layer by layer, 0.15mm at a time. These parts would then be assembled with welded, bent and fabricated parts for the initial prototypes. The Amanda Manufacturing team then performed final assembly and painting, preparing the prototype vehicles for Deshler to take to SEMA.

Reception

While in Las Vegas, the bumpers and doors, alongside the Amanda Products SpeedHook™ (a previous SEMA Global Media Award winner), attracted substantial attention. Attendees were impressed to discover innovative, eye-catching designs that were also aftermarket-ready and fully manufacturable. Both things didn’t often happen at once.

The press also took note, with CRAWL Magazine Editor and Publisher John Herrick remarking that “Amanda Products jumped into the off-road game with both feet,” calling Deshler’s ideation and prototyping process story an “interesting read in learning what people want and how to provide it while building a name in a new environment.”

At a subsequent SEMA Show, Deshler ramped things up considerably, revealing its Amanda Products suspension concept, a patented independent front suspension (IFS) and independent rear suspension (IRS) conversion kit for the Jeep Wrangler JK.

During SEMA, attendees repeatedly marveled at the suspension’s floating differential design. It builds on off-road racing advances and “moves the differential…to one side of the vehicle, while pivoting the differential in the center of the vehicle, center of the in-board-mounted CV on the passenger side.”

Featuring 16” of extended wheel travel and an effectively 27”-wide axle length out of a stock-width JK, it also neutralizes chassis roll with a camber compensating a-arm front suspension geometry. To kick up the stability even further, for the last three inches of droop, the wheel gently pushes outwards.

Nitto DrivingLine recognized its “fully independent front and rear suspension setup…that [adds] 16 inches of wheel travel up front and 14 inches out back” as one of its “Top 10 New Products” from SEMA.

Over time, Deshler’s prototype work has moved far ahead of building and selling things. It’s an ongoing opportunity to stretch the limits of the companies’ skills, experience and capabilities, to learn, to push beyond existing success in high-volume manufacturing. Removing barriers, encouraging collaboration and welcoming ideas, from wherever they come. This is the Deshler approach. This is how the Deshler partner companies are continuing to grow. Integrated. Together.